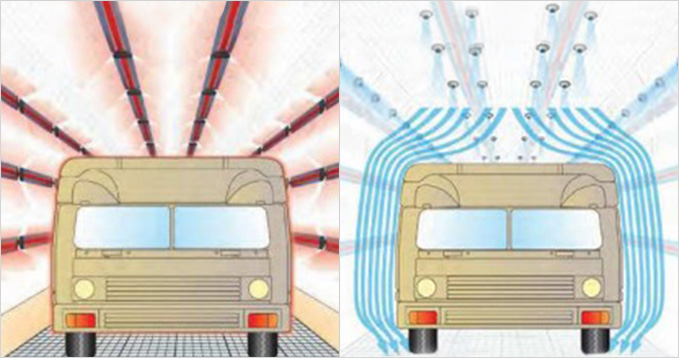

Drying properties of water-based paintIntensive Drying

can be translated into English as "Can achieve property drying by spraying air at a speed of 3 ~ 6m/sec

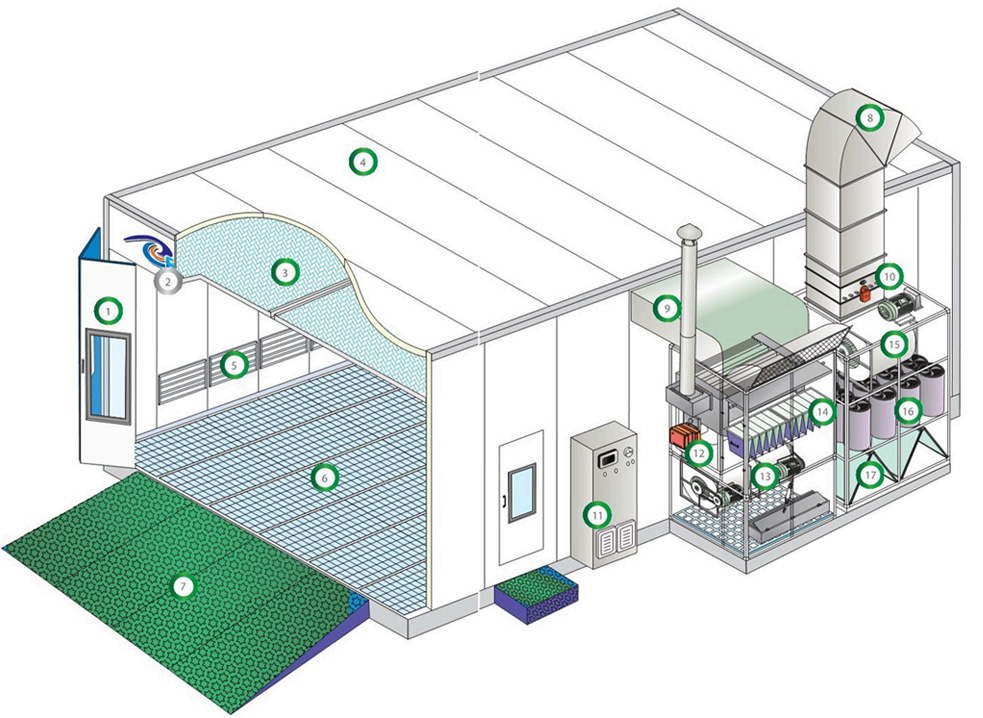

Oil-soluble paint combined booth principle

The drying process for volatile solvent-based paints involves the use of heat and a small amount of air, whereas water-based paints utilize a large volume of air to induce moisture evaporation. This system necessitates specialized technical capabilities to control the direction, speed, and quantity of airflow. Fine Auto Systems Co., Ltd. has achieved groundbreaking technological development in a dual-purpose paint coating/drying system for both solvent-based and water-based paints. This innovative technology not only effectively controls the flow of intake and exhaust air but also recycles waste heat through recovery and circulation methods. As a result, it offers significant cost-saving benefits and reduces work time by 30%, thereby maximizing operational efficiency.

01

can be translated into English as "Can achieve property drying by spraying air at a speed of 3 ~ 6m/sec

02

Infrared drying enhances the bond between the surface itself and the paint, enabling high-quality painting

03

Not only does it reduce the working time, but also it allows for a 30% cost saving as it does not use fossil fuel furnaces

04

Coating booth compatible with both water-based and oil-based paints (Patent No. 10-12096417)

65% of energy savings, rated best in its class for energy recovery system

Space saving medium paint booth 15000-5500-4500(internal)

160 high output Phillips radiation lamps providing natural light effect

Keep quite and stabilized temperature (the biggest energy saving effect)

by operation of special drying mode

Wide entrance doors of 4,000mm, 4-fold

Install 40 each V.O.C tower with minimum resistance

Exquisite fan work caused by VFD Inverter System

Fire prevention by installing 60T fiberglass wool insulator

21 hidden filter frame structures that stabilize air volume, and allow easy change filters

With full down draft system, smooth air circulation and best drying circumstance

Maintain intensity of illumination without dead zone for entire space loading lamp on the inclination plate of the upper side corner

The Outside View

Energy Recovery System

VFD Control Box

Air Foil Fan

* Option : Turbo Fan

V.O.C Tower

Heat Exchanger

| External Size | L15,120 x W5,620 x H5,200 | Main-Door | W4,000 x H4,500 / Four pairs | ||

|---|---|---|---|---|---|

| Internal Size | L15,000 x W5,500 x H4,500 | Workman-Door | W800 x H2,100 / 2set with window | ||

| Panel Materials | Glass Wool 60T Fire Resistant Panels | Lighting | Ceiling | 22units 4x32w | |

| Filter | Pocket filter, Paint-stop filter, Pre-filter, Ceiling filter, Floor filter, V.O.C tower(40EA) |

Wall | 18units 4x32w | ||

| Exhaust | Fan | Air Foil Fan | Intake | Fan | Air Foil Fan |

| Motor | 18.37 kw(25HP) X 2 units VFD Inverter System |

Motor | 7.5kw(10HP) X 4 units VFD Inverter System |

||

| Air Volume CMM | 600 ㎥/min | Air Volume CMM | 600 ㎥/min | ||

| Energy Recovery System | Standard Size : L1,300 x W1,400 x H1,400 | ||||

※ Try moving left and right.